Cement kiln refractories

Refractories play a critical, if unseen, role in both the rotary kiln lining, and the lining of the high volume static equipment areas that comprise a modern pre-calciner kiln system.

The durability of the rotary kiln brick lining generally determines the duration of a kiln operating campaign. Whilst great efforts are made to ensure appropriate refractory brick materials selection, installation, deployment (zoning) and the optimisation of the kiln light-up, it is primarily the nature and stability of the subsequent kiln operation that influences rotary kiln lining life.

Installing a new brick lining in the outlet zone of a precalciner kiln.

Installing a new brick lining in the outlet zone of a precalciner kiln.A large number of kilns now use alternative fuels. Many of them substitute these alternative fuels through the main kiln burner as well as in the pre-heater / pre-calciner; the chemical and heat-release changes caused by inevitable short-term fluctuations in the fuel(s) mix has a major influence on the thermal, coating and atmosphere conditions existing through the rotary kiln into the pre-calciner.

Expert systems are available that help limit the influence of fuel mix fluctuations on the flame shape, but not many cement kilns are equipped with such systems. Consequently, the main influence of the use of alternative fuels is often on clinker chemistry due to the different ash compositions of individual alternative fuels.

Such fuel variations may produce any or all of the following:

- Alternative fuel fall through ( from the pre-heater/ pre-calciner )

- Adverse minor phase re-circulation effects (gasriser )

- Excessive build-up or clogging ( kiln inlet or gas riser )

- Excessive coating in the rotary kiln (ring formation )

- Reducing conditions or damaging atmosphere effects( rotary kiln )

- Thermal wash-outs ( rotary kiln )

- Fluctuations in flame length ( rotary kiln )

- Destabilisation and stripping of clinker coating (rotary kiln )

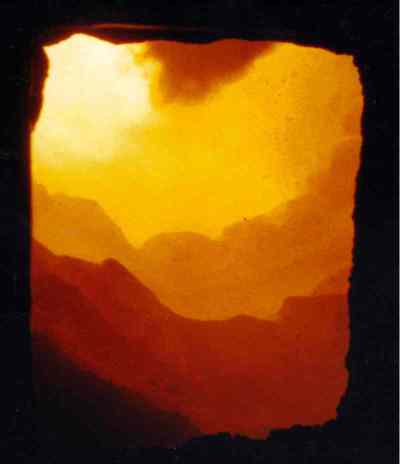

Demolition of worn lining in the burning zone of a 6.1 m diameter kiln.

Demolition of worn lining in the burning zone of a 6.1 m diameter kiln.Much can be learned from the clinker chemistry and microscopy about the environment existing within the kiln system. The clinker mineralogy, microstructure, minor phases, macrostructure and variability can each help to define more precisely the atmosphere and process conditions existing in the rotary kiln and clinker cooler. If any of the clinker parameters are found to be outside a safe range, or potentially indicative of conditions damaging to the coating or to the kiln refractory, kiln operators can use this information to attempt to achieve safer and more stable kiln conditions, thus reducing thermal and chemical stresses on the kiln lining.

Kiln outlet zone, with coating rings caused by fuel ash bonding with dust recirculating from the clinker cooler.

Kiln outlet zone, with coating rings caused by fuel ash bonding with dust recirculating from the clinker cooler.Get a Better Understanding of Cement

Articles like this one can provide a lot of useful material. However, reading an article or two is perhaps not the best way to get a clear picture of a complex process like cement production. To get a more complete and integrated understanding of how cement is made, do have a look at the Understanding Cement book or ebook. This easy-to-read and concise book also contains much more detail on concrete chemistry and deleterious processes in concrete compared with the website.

Click here for more information

Check the Article Directory for more articles on this or related topics