Measuring mortar porosity

Measurement of mortar porosity can be carried out by petrographic methods, typically using thin-sections and a petrographic microscope but now increasingly using scanning electron microscopy and polished sections. A while ago, I was asked by Dr Beningfield, of Neil Beningfield and Associates Ltd. who operate worldwide, to contribute to an interesting project concerned with the measurement of the porosity of mortar. An account of this work was published in Masonry International.

When fresh mortar is transferred from a trowel onto bricks or blocks, the rheology of the mortar changes immediately as water is drawn out by suction. The objective of the project was investigate how this affects the mortar microstructure and, in particular, whether the initial air content of mortar in the plastic state, based on measurements from a pressure device (eg: BS EN 1015-7:1999), can be related to the porosity of hardened mortar using petrographic methods.

Test panels of three concrete blocks were prepared by Stephen Farrell of CPI Ltd, Republic of Ireland, using high suction and low suction blocks. Two mortars were used, one air-entrained and the other not. Additionally, different curing conditions were tested by preparing mortar prisms from the two mortars. One set of prisms was cured under “good” conditions at 100% relative humidity and the other set simulated “poor” curing by immediate drying at 60 degrees C in an oven.

Method of measurement of mortar porosity

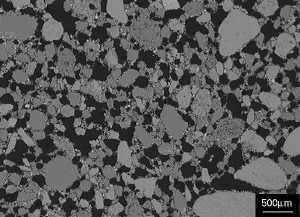

My contribution to the work was to measure the porosity of the hardened mortars. To do this, I prepared polished sections from which I measured mortar porosity using digital image analysis of a series of backscattered electron images. I used SEM images rather than optical microscope images as the backscattered image of a polished section gave better definition of the pore edges than an optical microscope image of a thin-section.

Figure 1 Backscattered image of polished section of air-entrained mortar, showing sand grains bonded with cement hydration products. Black regions are voids, infilled with epoxy resin.

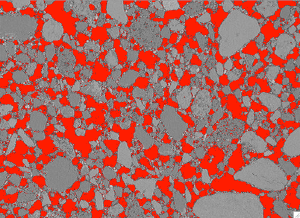

Figure 1 Backscattered image of polished section of air-entrained mortar, showing sand grains bonded with cement hydration products. Black regions are voids, infilled with epoxy resin. Figure 2 Same image as in Figure 1, with black regions, corresponding to epoxy resin in pores, highlighted in red.

Figure 2 Same image as in Figure 1, with black regions, corresponding to epoxy resin in pores, highlighted in red.The total area in red in Figure 2, as a proportion of the image area, is the mortar porosity as determined by this method. In this image, the mortar porosity was 31%.

We found that the void space as measured by image analysis was typically some 60% higher than the initial air content of the mortars in the plastic state. From this, we concluded that petrographic analysis of hardened mortar cannot be used as a measure of the initial air content of that mortar in the plastic state. Part of the difference is due to loss of water from the mortar due to suction. The two methods of testing – plastic mortar by standard pressure methods and hardened mortar by petrographic methods – are measuring different properties.

This project was designed and co-ordinated by Dr Neil Beningfield. Neil has been kind enough to ask me to be involved in numerous interesting projects requiring microscopy. He is an internationally-recognised expert, specialising in on-site investigations of problems and defects in masonry, renders and floor screeds. Neil can be contacted through his website at: http://www.beningfield.com

The paper title and reference is:

“An Interim Investigation into Pore Formation in Masonry Mortar and the Use of Microscopy to Investigate the Probable Initial Air Content.”

Beningfield N, Winter N and Farrell S. Masonry International Vol 25 No 1, 9-18, 2012.

Abstract

This paper uses a series of laboratory investigations to study mortar pore structure, then discusses a theoretical proposition that is confirmed by the practical work outlined in the paper. The research confirmed that microscopy is a valuable tool in elucidating the pore structure of hydrated cementitious materials, typically concrete and mortar but, particularly in the case of the latter, it is fallacious to equate the total void space in the hardened mortar with the initial air content. Indeed, any relationship is tenuous.

This work used scanning electron microscopy of polished sections of mortar to elucidate the pore structure and investigated the changes in pore structure as a function of unit type and suction, curing condition and initial air content. The effect of mortar joint orientation was also briefly considered.

The results showed that the total hardened mortar pore volume, which approximates to the porosity, differs greatly from the initial air content in the wet or plastic state, and showed that measurement of the former, the total hardened pores, cannot be used to state a value for the initial plastic air content.

Check the Article Directory for more articles on this or related topics